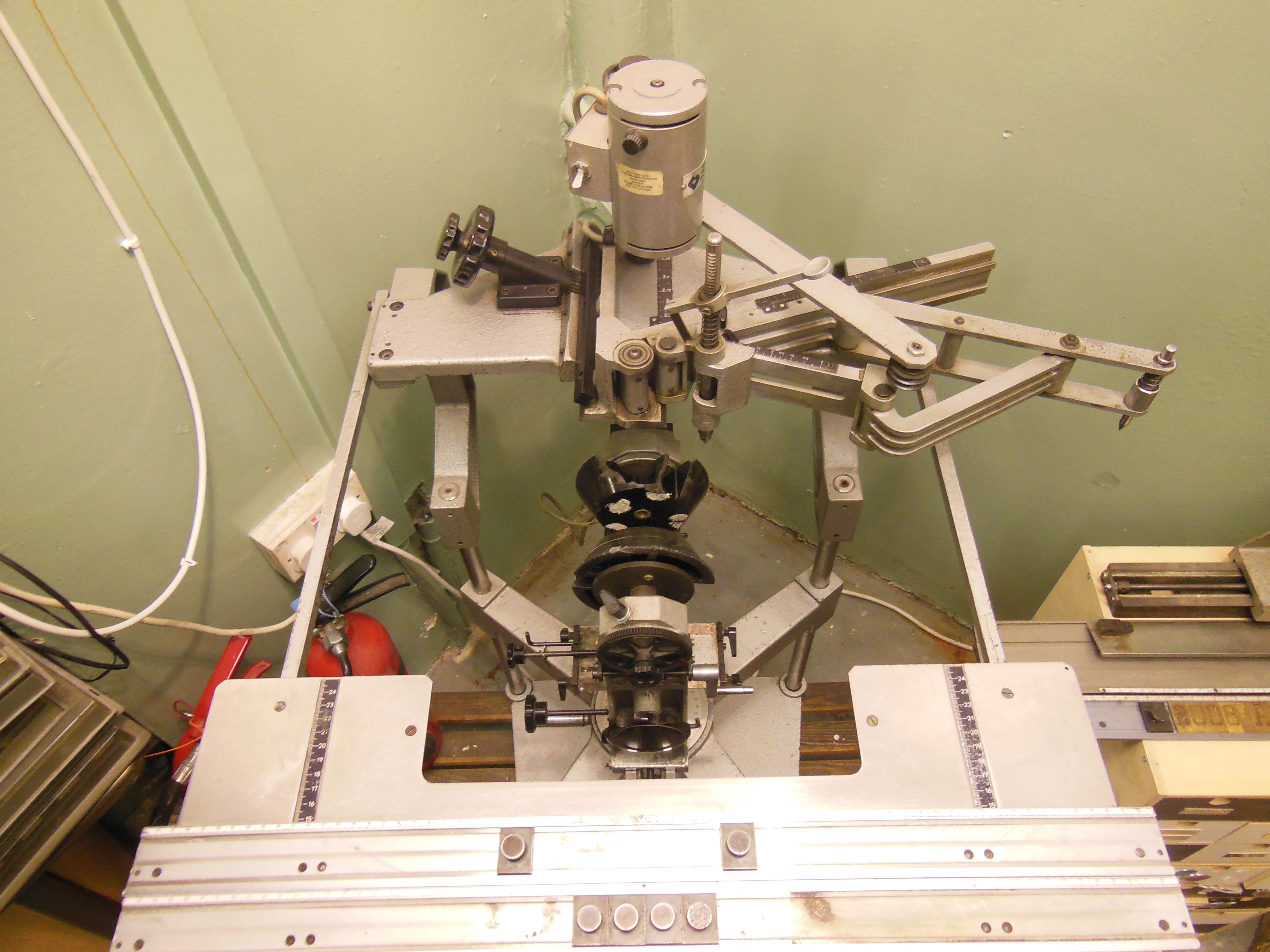

The Gravograph Pantograph Engraving Machine: A Historical Overview

Origins and Development

The Gravograph pantograph engraving machine has played a significant role in the history of engraving, revolutionising the way intricate designs and inscriptions are etched onto various materials. This article aims to provide a comprehensive overview of the history, usage, key features, and significance of the Gravograph pantograph engraving machine, as well as its notable advancements over time.

The origins of the pantograph engraving machine can be traced back to the 17th century when Christopher Schissler, a German inventor, developed the first pantograph device for copying and scaling drawings. However, it was not until the 20th century that the pantograph engraving machine was widely adopted for industrial engraving purposes. The Gravograph pantograph engraving machine, developed by Gravograph, a global leader in engraving technology, has been at the forefront of this technological advancement. The company has been consistently refining and enhancing the pantograph engraving machine since its inception, making it a versatile and indispensable tool for engravers across various industries.

Key Features and Capabilities

The Gravograph pantograph engraving machine is renowned for its precision, efficiency, and versatility. Key features of this machine include:

- Variable Ratio Pantograph:

- This feature allows the operator to maintain the exact proportions of the original design while scaling it to the desired size, ensuring precise replication.

- Rotating Spindle:

- The machine is equipped with a rotating spindle that accommodates various engraving cutters, enabling the engraving of intricate designs and fine details on different materials.

- Intuitive Software Integration:

- Modern Gravograph pantograph engraving machines are integrated with user-friendly software that facilitates the translation of digital designs into physical engravings with utmost accuracy.

The machine is capable of engraving on a wide range of materials, including metals, plastics, wood, and acrylics, making it a versatile solution for diverse engraving needs.

Significance in the Field of Engraving

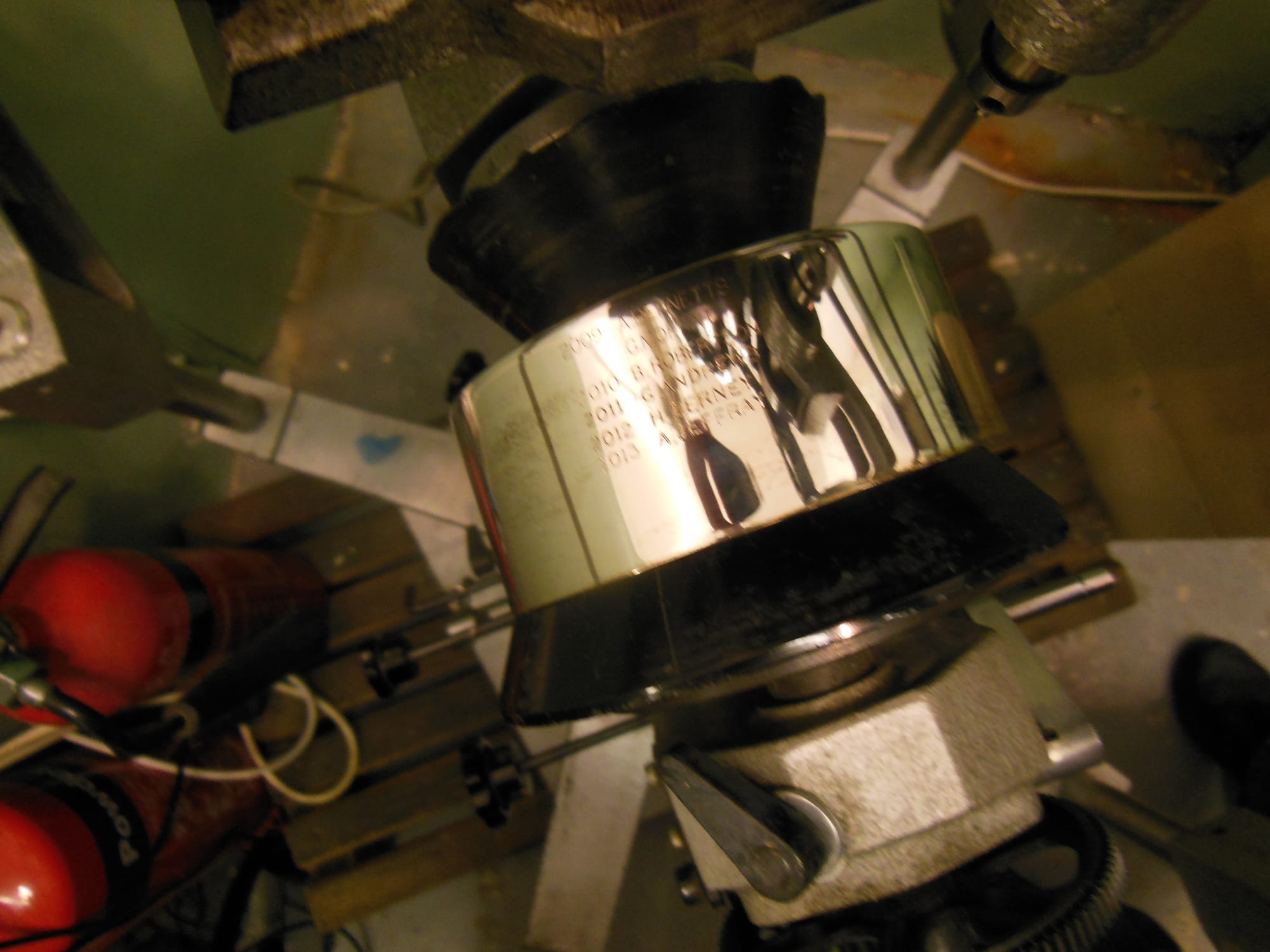

The Gravograph pantograph engraving machine holds immense significance in the field of engraving due to its unparalleled precision and reliability. It has been widely embraced by professionals in industries such as jewellery making, signage production, industrial part marking, and personalised item engraving. The machine's ability to deliver consistent and high-quality engravings has made it an indispensable tool for businesses and artisans alike.

Advancements and Modifications

Over the years, Gravograph has continuously improved the pantograph engraving machine to meet the evolving needs of engravers. Notable advancements and modifications include:

- Enhanced Automation:

- Automation features have been integrated into newer models, streamlining the engraving process and increasing productivity.

- Laser Engraving Integration:

- Some models now offer the option to integrate laser engraving capabilities, expanding the machine's engraving capabilities to include more intricate and complex designs.

- Improved Ergonomics:

- Emphasis has been placed on ergonomics, making the machines more user-friendly and reducing operator fatigue during prolonged use.

Conclusion

In conclusion, the Gravograph pantograph engraving machine has a rich history and has continually evolved to meet the demands of modern engraving applications. Its precision, versatility, and significant impact on the field of engraving make it an invaluable tool for professionals and enthusiasts alike. As technology continues to advance, the Gravograph pantograph engraving machine will certainly remain a cornerstone of the engraving industry, providing innovative solutions for years to come.